Building and Automating a Hydroponic System

I’ve been growing various herbs, lettuces, and other food plants using hydroponics for some time now. It’s a fantastic method for producing fresh veggies year-round. Recently, I’ve taken my interest a step further by designing my own hydroponic systems. Below, you’ll see my test bed, which I’ve been using to experiment with different setups.

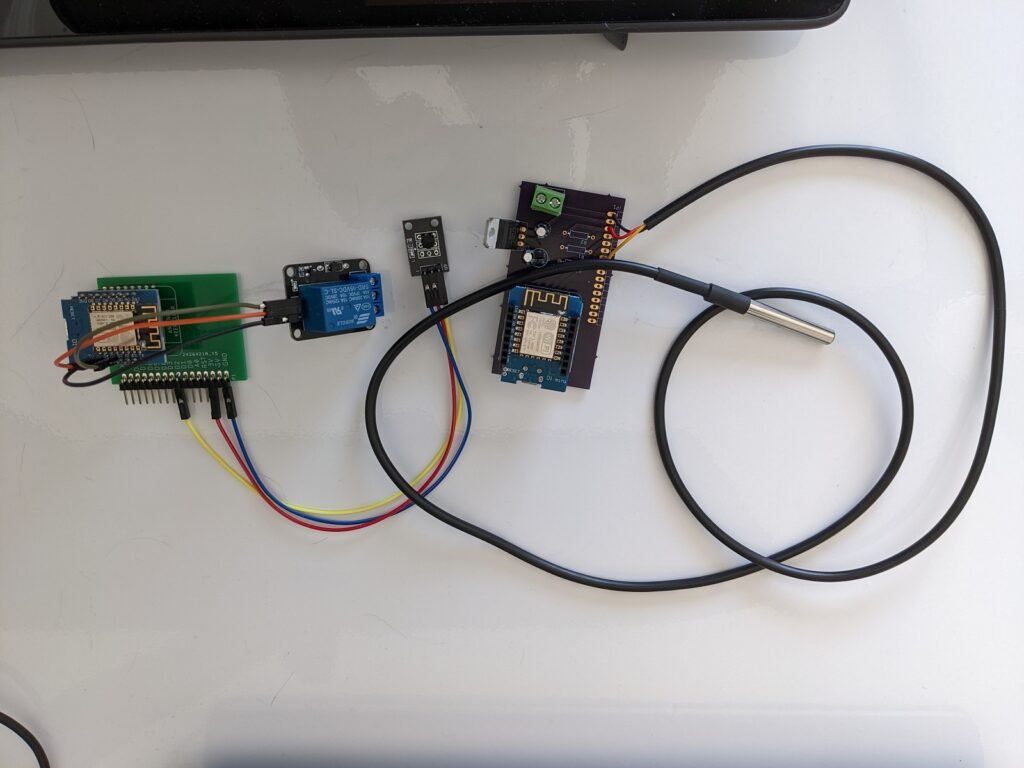

I also have been working on a few iterations on various sensors to automate the rig.

Project Goals

My main goal is to create a closed-loop hydroponic system. This means that both the lights (for indoor setups) and the pump will be powered by solar energy, reducing operating costs and making the system more sustainable. Additionally, I plan to automate the system using sensors and various actuators to improve efficiency and ease of use.

Current System and Future Plans

Horizontal to Vertical Transition

Currently, my hydroponic system is horizontal, but I plan to transition to a vertical system. This change will allow me to grow more plants within the same footprint, maximizing space efficiency.

Pump Upgrade

The system now uses a 110V AC pump, which I intend to replace with a 24V DC pump. This switch will make the system more efficient when powered by solar energy, as it eliminates the need to convert DC to AC.

Lighting System

The current lights are 110V, but I am designing a new lighting system that will run on 24V DC. This will not only reduce energy consumption but also make the lights controllable through the automation system.

Automation and Sensor Integration

Sensor Design

For automation, I am using the ESP8266 WiFi-enabled microcontroller with the Arduino toolkit. The ESP8266 is an excellent choice due to its affordability and sufficient processing power for this application. Here’s a breakdown of the sensor setup:

- Configuration: Loaded through a JSON document via the serial port on new devices, including WiFi network details and other settings.

- Communication: Sensors communicate with a local RabbitMQ server using the MQTT protocol. Sensor data is sent as JSON documents, and control commands are also handled via MQTT.

Current Sensors and Data Collection

The sensors currently deployed include a temperature probe that sends a reading whenever there’s a 0.5°C change (this threshold is configurable). A Python program running on a dedicated machine subscribes to the sensor’s MQTT topic and records the temperature data to a CSV file.

Future Work

I am working on finalizing the base sensor design, which will include:

- Power Supply: Ensuring reliable and efficient power for all components.

- Sensor Integration: Adding various sensors and actuators through add-on boards to extend the system’s capabilities.

Summary

This hydroponic project aims to create a sustainable, automated, and efficient system for growing plants. By transitioning to solar power, upgrading pumps and lights, and integrating advanced sensors, the system will be capable of maintaining optimal growing conditions with minimal manual intervention. This approach not only maximizes space and resource use but also provides a scalable solution for home or commercial growers.

Need a Creator Alchemist on Your Project?

I’m available for hire—consulting, systems design, embedded tech, creative problem-solving, or anything in between.

If you’ve got a project that needs someone who can think it through and build it out, I’m interested.

👉 Let’s Talk

jamie@jamiestarling.com